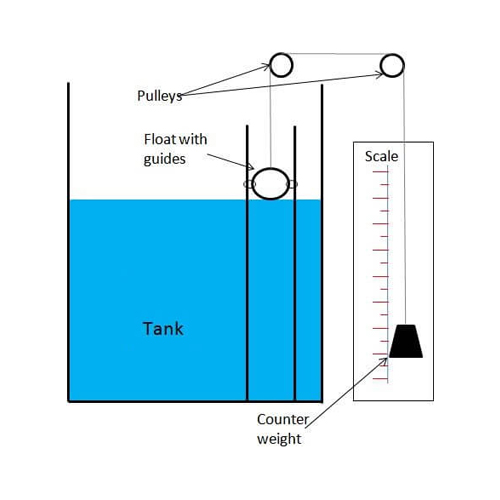

Chain And Float System

One common form of level measuring system uses a tape or servo motor which is connected to a float. The height can be read as the float moves with liquid level.

Float devices use the buoyancy of a float to indicate the liquid level in the tank. One common approach is to attach the float to a chain. The chain is attached to a counterweight which indicates the level as the float moves up and down. These types of device are often found on large atmospheric storage tanks.

Other devices transfer the buoyancy force to a metering device using a torque tube. The float is connected to the torque tube which twists as the height of the displacement device changes. The twisting force drives the position of a pointer which then indicates liquid level.

For some applications – where the liquid is corrosive, toxic or in some way hazardous – a magnetic level gauge is used.

The float contains a magnet which changes the orientation of small indicator wafers as it moves up and down.